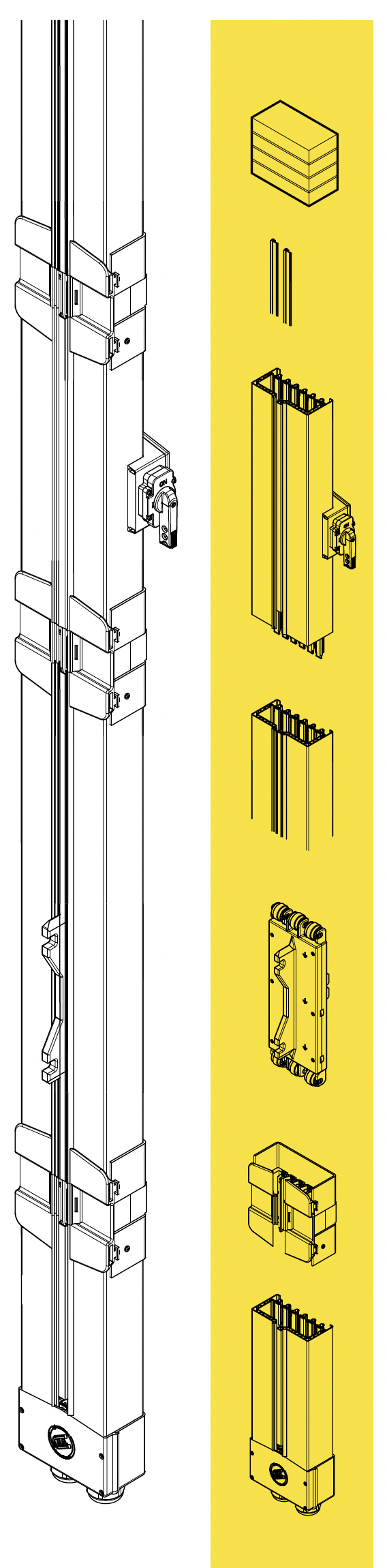

VERTICAL BUSBAR » TRV SERIES

Designed for lifting tasks in Material Handling Systems and Outdoor and Construction Site Lift Technology.

VERTICAL BUSBAR SYSTEM WITH 6 PRE-MOUNTED CONDUCTORS

Energy transmission system fitted with 6 conductors with joints. Operating current: 50, 100 or 160 A, depending on the busbar. Vertical layout suitable for construction site lifts.

It is composed by the following components, available on request:

- TRV06P006 – End cap: Close and protect the end of the busbar.

- TR6012 – Gasket: In high-performance elastic PVC.

- TRVS06P160 – Switch disconnector: The switch allows to interrupt current within a TRV line to allow the line to be extended in length without having to intervene on the main switch. Only on specific request.

- TRV06P… – Insulated bar 50A / 100A / 150A: Rigid PVC housing with 6 enclosed copper conductors. At each extremities, the copper strip has connector for electrical and mechanical connection with next bar.

- TRV06P011 – Trolley current collector: To provide power to construction hoist. Carbon brushes with springs guarantee uniform electrical contact.

- TRV06P001 – Connection box: Composed by a joint box, baseplate with connectors and two joint covers. Connectors are mounted on a baseplate. The phases on busbar are engaged to it guarantee both mechanical and electrical continuity.

- TRV06P003 – Feeding box: Composed by insulated bar, it provides connection between system and cable inside the relevant box.

SMART SOLUTION AVOID THE CONVENTIONAL CABLE DISTRIBUTION SYSTEM!

This system has some advantages:

- Optimization of space.

The compact design of the cable-free bar allows optimization of installation and use space.

- It is the safety response to a problem that has never been solved.

It can solve the problem of conductor interruption in the power cable currently used to power construction site elevators. There is no problem of damage or wear on

the cable.

- Provides easier and faster installation.

The interlocking modularity of the individual

components means that no tools are needed for installation and less construction work means less expensive installation.

- Flexibility of use.

Compatible with any type of structure and any configuration.

It is a unique solution, an excellent alternative to cable replacement.

One solution for reducing installation costs, increasing product life, ensuring that the operator cannot come into contact with exposed electrical parts, and allowing the line to be reused on other installations.

You can get advice on line construction and receive the instruction manual by sending your request by e-mail to giovenzana@giovenzana.com or by contacting the sales representative in your area.

Choose the right person in our sales network.